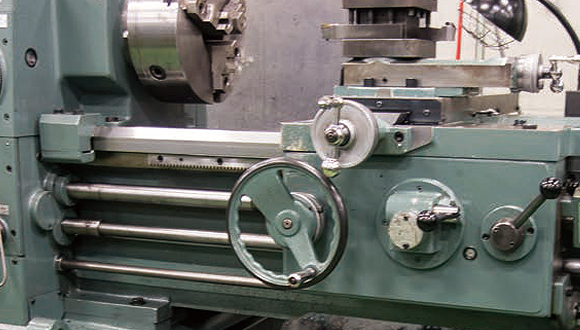

Cemented carbide is processed to the desired dimensions by grinding the outside diameter and height. Steel materials are cut, machined with a lathe or milling machine to the desired shape and allowance, and then heat-treated by quenching. The treatment increases hardness and performance and makes the material stronger.

Precision Machining Process

Machining

Heat Treatment

Assembly

The cemented carbide and steel are assembled to form a single part. There are two types of assembly methods: a shrink fit using heat and a press-fit using pressure.

Machining

Molds are machined to the desired shapes and dimensions by means of CNC lathe machining, diemilling EDM and wire EDM.

Finishing Process

Surface Treatment

Since the surface of the mold is transcribed to the product, it is polished to a mirror finish. In addition, a coating is applied to improve the surface characteristics.

Inspection and Shipping

We check each dimension, shape, and mirror surface condition using three-dimensional measuring machines and shape measuring machines, and pack the products to prevent scratches and rust before shipping.