Special Materials

UR-C Series

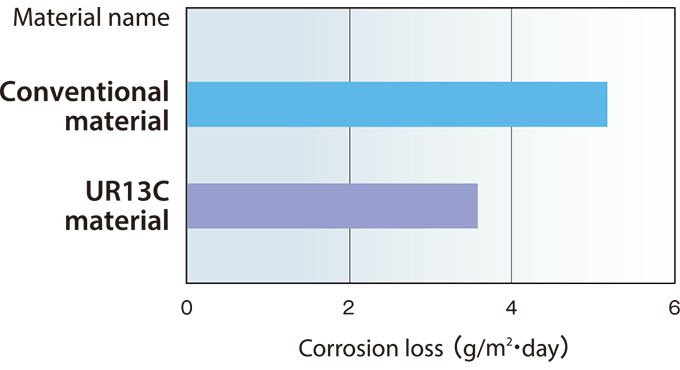

UR-C material is a fine-grained alloy that utilizes the binder phase strengthening and modification technologies for R-based materials. Compared with conventional materials (equivalent to JIS classification VM-40), UR-C material has improved strength while maintaining hardness. Another major feature of this alloy is its improved corrosion resistance and chipping resistance.

These characteristics make it ideal for products that require sharp edges, abrasion resistance, and corrosion resistance.

Mechanical Characteristics

| UR10C material | UR13C material | Conventional material | |

|---|---|---|---|

| Hardness (HRA) | 91.5 | 90.5 | 90.5 |

| Specific gravity | 14.5 | 14.2 | 14.7 |

| Deflective strength(N/mm2) | 4000 | 4100 | 3200 |

Corrosion Test Result (10% hydrochloric acid immersion test)

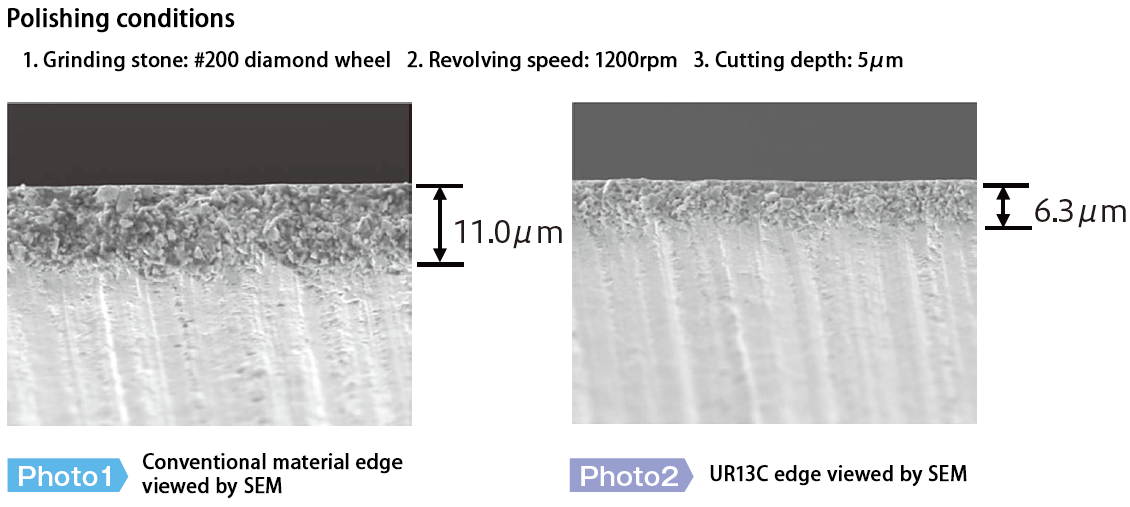

Chipping Resistance Test Result

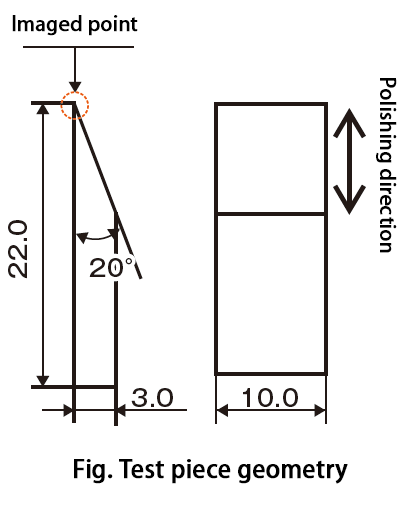

As shown in the figure below, a sharp edge was processed by grinding, and the edge microstructure was observed with an electron microscope. As a result, the chipping layer could be reduced to 57%, which indicates that the chipping resistance has improved compared to conventional materials.