Several types of raw powder (tungsten carbide, cobalt, etc.) are uniformly mixed. Grain size and ratio vary depending on the type of material.

Cemented Carbide Production Process

Formulation

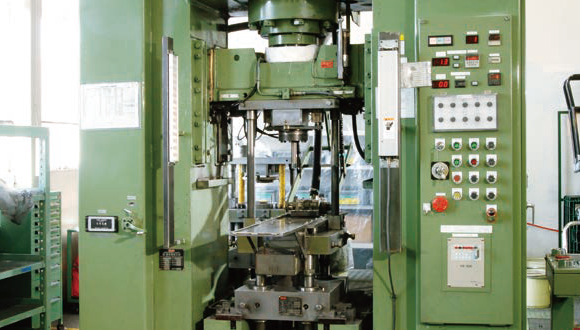

Pressing

The blended raw materials are packed into a mold and pressed into cylinders or blocks. Pressing methods and molds vary depending on the shape of the product.

Pre-sintering

The pressed and hardened material is heated to 600°C to 1000°C to harden it to a level hard enough for forming.

Forming

The product is formed into the shape in the instruction drawing, taking into consideration the amount of shrinkage during sintering and the machining allowance after sintering.

Sintering

The molded product is heated to 1300°C to 1500°C and completely hardened.

The cemented carbide is complete.

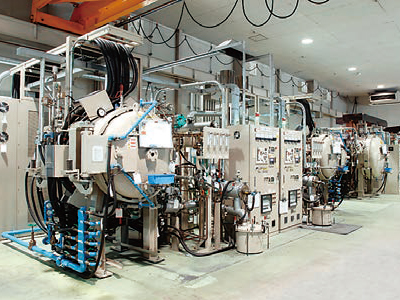

HIP

(Hot Isostatic Pressing)

Inspection and Shipping

We check whether the dimensions are in accordance with the drawings and for any abnormalities in the appearance of the product. The products are carefully packed to prevent chipping and shipped nationwide.